Not Everything is AI, Part 2: How Clothes Get Made with 3D Tech

3D tech, real shifts, and what it means for your career

Welcome back to Part 2 of this 3D series ✨

In Part 1, we looked at how 3D is transforming fashion marketing.

If 3D in marketing is the flashy front row, 3D in garment development is the backstage hustle—less visible, but arguably more transformative.

In this article, we’ll cover:

• How the traditional design-to-sample process works—and where it still falls short

• What 3D Tools actually do and how the technology has evolved

• Where 3D becomes a creative advantage

• Where the industry stands with this technology

• Plus: a helpful framework for navigating this tech shift, tailored to where you are in your fashion career

If you work in fashion design or aspire to become a thought leader, it’s worth paying attention to. Let’s get into it. 👇

HOW THE TRADITIONAL PROCESS WORKS

Traditionally, most designers have relied on 2D sketches as the initial step in developing a garment—whether they’re done by hand or in Illustrator. Once a design feels promising in sketch form, the next step is patternmaking—often guided by technical packages and reference garments for fit or measurement. From there, you cut a sample—usually in a substitute fabric, since the real one might be too expensive to waste on early rounds.

This process repeats multiple times: sample, adjust, resample. And in the meantime, what you imagined at the sketch stage often changes. Maybe that detail you loved looks awkward in sample form. Maybe the fit just doesn’t translate. Maybe your “oversized” vision was different from your design boss, your patternmaker, or your merchandiser. Misalignments like these usually don’t surface until you’re holding a physical sample—and by then, time and budget are already ticking.

This is why brands typically bake in 3 to 5 months of design and development time in the calendar before showing the collection to buyers. That means the design process often kicks off nearly a year before the collection hits stores. And we all know the pitfalls of designing that far ahead.

WHAT 3D TOOLS CAN DO

Now, 3D design/ development programs like Clo3D, Browzwear and Optitex aim to cut much of that time (and cost) by moving the trial-and-error process in-house.

Imagine you’re handing off a 2D sketch to your patternmaker or maybe you’re the designer building the pattern yourself digitally. But now, with these 3D programs, the digital pattern pieces can simultaneously simulate as a garment on an avatar in your preferred size and body type.

If you’ve never seen these programs in action, it might be hard to picture—so here’s a quick link to get a sense of what they do:

The designer and patternmaker—or the designer alone—can review the style in 3D, make live edits, test materials, and align on fit intent—all before cutting a single sample.

HOW 3D SOFTWARE HAS EVOLVED

Now—these programs aren’t exactly new. They’ve been quietly around for over a decade. But most fashion companies didn’t seriously explore them until the last 5 years, and even then, they were mainly used by technical and production teams, not designers. The pandemic pushed a lot more brands to finally test them, but even now, full 3D adoption is still very much a work-in-progress.

In the early days, 3D was positioned almost entirely as a mass-market, cost-cutting, efficiency tool. The first time I heard about 3D software was from a patternmaker I interviewed during the pandemic, who was doing freelance work for Walmart’s apparel division. She told me they had been using the 3D programs years ago—not for design or creative development, but to speed up bulk production, standardize fits, reduce sampling rounds, and keep margins tight.

That’s partly why many creative teams dismissed it early on. For luxury houses or design-driven brands, 3D felt too clinical, too stiff, too far removed from the drape, texture, and movement you need to actually feel when building beautiful product.

But in recent years, that story has started to shift. The tech has improved (a lot), the pandemic forced brands to experiment, and more teams are realizing that 3D might not just be a cost-cutting tool anymore—it might actually help solve creative problems too.

WHERE 3D BECOMES A CREATIVE ADVANTAGE

I’ve always believed the best design concepts begin with draping or fittings—when you’re physically working with fabric, playing with proportion, structure, and watching the way a garment really comes alive: how it moves, feels, and connects with the body in real time.

And while 3D tools are getting much more advanced—with walking simulation, gravity, and motion features—Millennial me still thinks they can’t fully replicate the creative sparks that happen when you interact with a physical garment or watch it move on a live model.

But even for a designer like me, there’s a huge advantage I see.

Fashion operates on brutal timelines. After spending over a decade working in design, I’ve seen how time and budget sometimes prevent designers from seeing physical prototypes before moving ahead to salesman samples—or even full production. Whether it’s a last-minute style added to fill an assortment gap, or a carryover style with minor updates, decisions sometimes have to get made without ever seeing a real sample. And that’s the part that always makes designers a little sick to their stomach—sending something into production blind, just hoping the balance, fabric, and proportions land the way you imagined.

That’s where 3D can fill the gap. You can visualize how a style will look and function—at least digitally—without cutting a sample. It helps prevent costly mistakes (and saves you from silently hating your own creation once it’s already out in the world.)

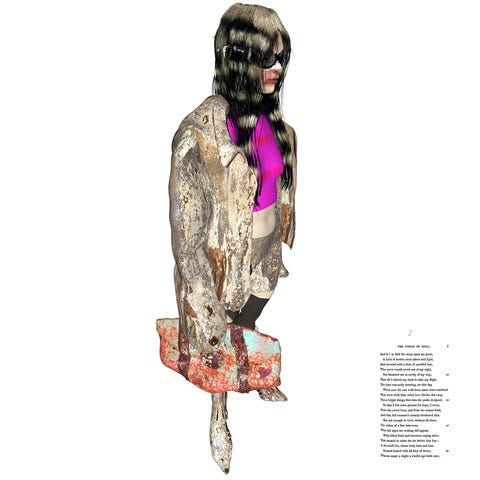

(Can you tell which is digital vs real here? I can’t tell… 🧐)

Another benefit is internal communication. In many cases, when proto samples are reviewed with your boss or merchandising partners, there’s still a lot left to the imagination—whether it’s subbed fabrics, off-colors, or early-stage fits. But with photorealistic 3D renderings showing the intended fabric, color, and silhouette, you significantly reduce the risk of misinterpretation—or worse, styles getting dropped too early.

If the raw 3D outputs feel too rough for creative reviews, you can also explore AI tools like The Fabricant to help polish the renderings into something closer to a final product. With just a prompt, they can turn your 3D file into a full-on photorealistic render—complete with background, lighting, and model—tailored to your aesthetic and vibe.

Of course, you’ll need to learn how to prompt to get the results you want (just like AI image generator)—but once you do, the creative possibilities open up fast.

Here’s a peek at what that looks like on their Instagram. (And no, don’t judge the aesthetic here—you can definitely do better.) 😛

The beauty of 3D design is that it doesn’t have to be all-or-nothing.

Depending on your team size, product type, and creative process, you can adapt it where it makes the most sense. Some brands may apply 3D primarily to more straightforward categories—where creative risk is lower. Others might take a hybrid approach: developing key, emotion-driven styles through traditional hands-on methods, while digitizing the more repetitive or volume-driving styles for speed and efficiency. And for some companies—especially those working on basics, replenishment, or seasonal refreshes—a fully digital development flow may eventually become the norm after a transition period.

WHERE THE INDUSTRY STANDS

In theory, this shift could help brands develop collections faster, reduce waste, and minimize shipping—while giving designers more opportunities to perfect their styles without the usual constraints.

So why hasn’t it been widely adopted yet?

It’s technical. 3D programs require either a new type of talent or significant training — and right now, there are only a limited number of people in the industry who are actually trained on these programs. Not every brand is ready to invest time or money in that.

It challenges tradition. Fashion is still a hands-on industry. A physical sample holds trust in a way a simulation often doesn’t.

It’s still not a proven ROI. Most companies can’t afford to gamble on a system that feels experimental. The risk still feels high.

Still, big brands are starting to lean in. According to ChatGPT and its sources:

PVH (Tommy Hilfiger, Calvin Klein) is rolling out Browzwear across design teams and moving toward fully digital product creation.

Nike and Adidas use in-house 3D platforms to prototype before any physical sampling.

Zara and H&M are testing Clo3D to streamline development and reduce waste.

We don’t know how deep these integrations go yet—but the investment is clearly happening.

And as more fashion schools introduce 3D design tools into their curriculum, the next generation of designers is already getting trained to work this way.

Personally, I think the bigger opportunity lies with startups. For established brands, overhauling deeply rooted systems won’t happen overnight—but for new designers or manufacturers just building their workflow, it’s a chance to build smarter systems from the start—faster, more collaborative, and potentially more sustainable.

WHAT THIS SHIFT MEANS FOR YOU

If all this talk about new 3D software and tech integration feels overwhelming—you’re not alone. A lot of us are navigating this shift while trying to keep up with everything else on our plates.

I recently came across a YouTube Video (link here) that offered a helpful way to frame this moment, and it got me thinking about how it applies to fashion.

The idea is this: not everyone has to approach this tech shift the same way. Your experience level, career stage, and existing strengths should guide how you engage with tools like AI and 3D software—not a one-size-fits-all prescription like “learn Clo3D or get left behind.”

Here’s how I reframed it for fashion:

The Early Creatives (0–5 years into their careers):

You likely grew up with some 3D visuals, and digital-native workflows. If you’re early in your fashion journey, this is the time to go deep. Learn the tools. Experiment with simulations. Join teams where you can actually build things in 3D. You don’t need to master everything overnight, but your fresh perspective and willingness to play with new tools is a major asset. Build that muscle now.The Mid-Career Builders (5–15 years in):

You’re likely juggling real responsibilities—managing a team, overseeing categories, owning timelines and budgets. You don’t need to become a 3D wizard, but this is the time to evolve into a translator. Learn enough to communicate effectively with the 3D team or freelancers. Use your existing knowledge of design, product flow, and cross-functional pain points to spot where digital tools can actually make things better. Think of yourself as the bridge between creative vision and new execution tools.The Strategic Creatives (15+ years in):

At this level, your superpower is pattern recognition and long-view thinking. You’ve seen systems fail, processes repeat, and trends cycle. Your role might not be to open up Clo3D and design, but to ask the right questions: Can we use 3D to reduce waste? Can we cut sampling costs? Could we create a more inclusive sizing strategy using digital fittings? Your job is to guide teams toward smarter decisions—not necessarily to be hands-on with the tools, but to help define the why behind using them.

The key is to lean into your strength zone rather than trying to compete outside of it. This isn’t about replacing yourself with tech—or trying to reinvent your role overnight. It’s about adapting with clarity, not panic.

Long story short, 3D design tools might not be the flashiest tech in fashion, but they’re quietly laying the groundwork for a major shift in how collections are developed behind the scenes. The transition won’t happen overnight—but as a new generation of designers enters the field already fluent in these tools, change may come faster than we think.

This might be a good time to step back, assess where you are in your career, and think about how you can adapt these tools to serve your own growth and advantage.

In the final part of this series, we’ll zoom out to the selling side—from virtual showrooms to experimental metaverse spaces—and explore how 3D is reshaping the way fashion is pitched, presented, and bought. See you there. 🛍️